Triangulate your trajectory for business growth with Acuity Lasers

Triangulate your trajectory for business growth with Acuity Lasers

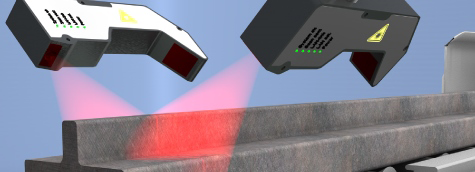

Acuity laser sensors satisfy diverse dimensional measuring applications for industrial automation and advanced research. Acuity sensors use laser triangulation, time-of-flight or confocal chromatic displacement measurement principles for highest accuracy position measurement installation. From texture profiling to measuring kilometers, Acuity Lasers can do it all.

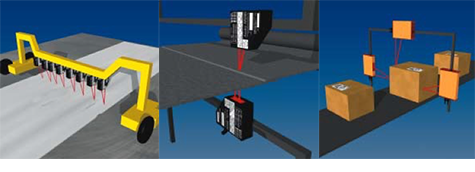

3D Profiling

The AccuProfile™ 820 Laser Scanners are Acuity’s high-accuracy sensors for industrial parts scanning. Merging the technologies of machine vision and displacement measurement, these compact profile scanners are ideal for in-line dimensions verification and reverse engineering of components. Common applications include dimensional verification of heights, widths, radius of curvature, gap width, surface separation, part length, hole diameters, etc.

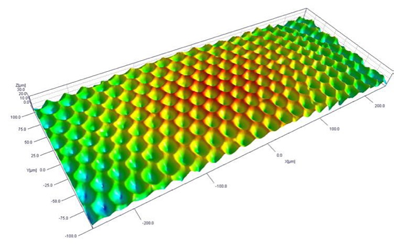

Texture Profiling

The CCS Initial confocal sensors measure distance and topography of varied targets, including silicon, polished metals, glass, contoured lenses, polymers, semiconductor masks and natural materials. The technology in these confocal sensors support nanometer-scale measurement resolutions.The high resolution and fast sampling speeds of Acuity’s laser displacement sensors make them versatile laser profiling sensors for many industrial and research applications.

High-res Linear Measurement

Acuity has Short range sensors and long range measurement lasers, which can scan anything from texture profiling to kilometers of length.

Harsh Environments

Acuity Laser has the ability to access and measure harsh environments from molten metal, to the lumber industry.

Triangulate your trajectory for business growth with Acuity Lasers

Triangulate your trajectory for business growth with Acuity Lasers