ROBOHAND Electric Grippers

With simple plug & play operation, no programming tuning or adjusting is required. “Light Switch” simplicity in a compact design for easy setup and no external control board.

- Fast actuation (0.25 seconds up to 150 PPM), 25 mm stroke and 111N / 25 lbf grip force

- 20+ million cycles with zero maintenance and 100% duty cycle

- Electrically Actuated: 24 VDC power plus discrete input for open/close operation. “Light Switch” simplicity for easy operation

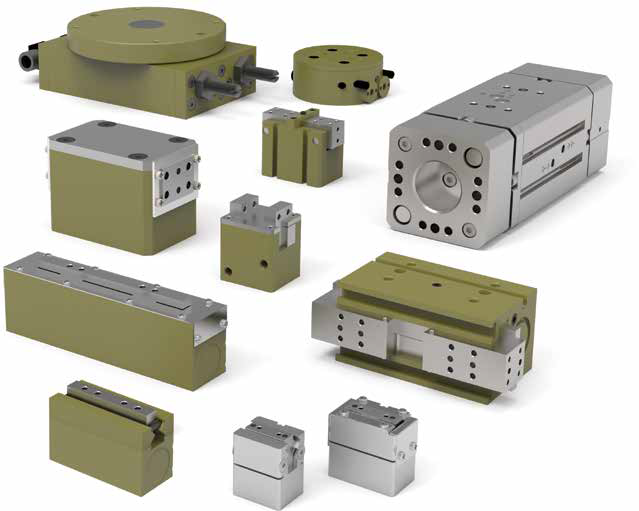

Robohand Grippers Pneumatic

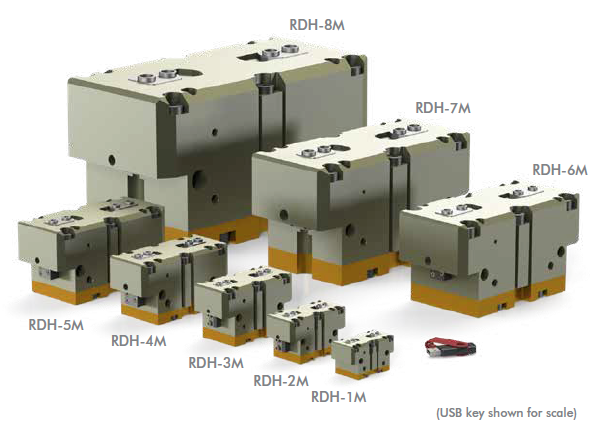

RDH Series

2-Jaw General Industrial Grippers

Features:

- Rugged multi-purpose powerful gripper

- 8 sizes for small lightweight to very large and heavy part gripping

- High impact resistant with double wedge design

- Shielded gripper to repel metal chips and particulates

- Spring assist option maintains grip in case of air pressure loss

- Purge and scavenge ports for harsh & clean environments

- Multi-position sensing up to 4 locations

Applications:

- High particulate application environments

- Automotive engine block and gantry systems

- Ideal for very heavy part gripping

RTH Series

3-Jaw Parallel Grippers

Features:

-

Rugged multi-purpose powerful gripper

-

8 sizes for small lightweight to very large and heavy part gripping

-

High impact resistant with triple wedge design

-

Shielded gripper to repel metal chips/particulates

-

Spring assist option maintains grip in case of air pressure loss

-

Purge and scavenge ports for harsh & clean environments

-

Multi-position sensing up to 3 locations

Applications:

-

Large round shaped parts

-

Automotive engine block and gantry systems

-

Ideal for very heavy part gripping

RP Series Industrial Parallel Gripper Rugged Impact Resistance 2-jaw

RP-5 RP-5M – 10, -11, -12, -15

Features:

- Widely used robust sealed design gripper

- Double wedge design for high impact applications

- Hardened steel bottom for part pressing applications

- Inductive jaw location sensing

- Grip force range from 178N [40 lbs] to 2669N [600 lbs]

- Stroke Range from 6.4mm [0.25 in] to 50.8mm [2.00 in]

Applications:

- Inline part pressing applications

- OEM machine pick and place

- Packaging applications

- Automotive assembly

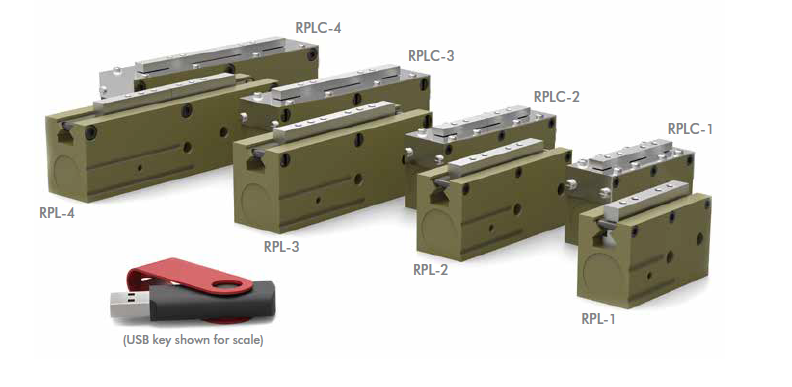

RPLC Series Gripper

2-Jaw Precision Parallel Grippers

Features:

- Excellent part positioning and repeatability

- Zero side play using low friction , Dual-V roller bearings

- Class 10 rated clean-room (RPLC), fits life Sciences

- Low friction for operation in low pressure applications – corrosion resistant design (RPLC)

- Optional non-synchronous jaw operation

- 30°C to +150°C [-20°F to +300°F] option Viton®seals

- Purge port (RPLC) prevent contaminants entering gripper

- Scavenge port (RPLC) prevents gripper grease

from contaminating environment

Applications:

- Clean room and harsh environments (RPLC)

- Delicate part handling with valve controls

- Long gripper finger requirements with precision

- High temperature applications using Viton® svea

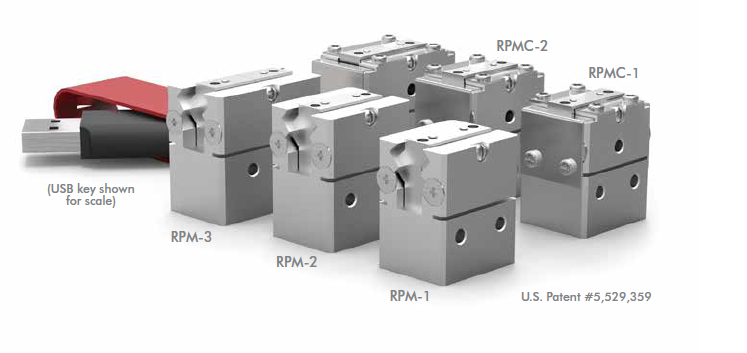

RPM – RPMC

Features:

-

Miniature gripper for small part gripping

-

Zero side play due to Dual V bearing system

-

Low friction and smooth operation for precise part position repeatability

-

Create compact gripper arrays with top manifold design

-

Adjustable pre-load screws eliminates side play over life of unit

-

Purge and scavenge ports for clean/harsh environment operation

-

Units are lubricated with clean-room grease

-

Class 10 rated clean-room (RPMC)

Applications:

-

Ideal for semiconductor and life sciences laboratory applications

-

Ultra small gripper for space constrained applications

-

Sealed design operates in harsh environments (RPMC)

-

Viton® seals option for High temperature applications

-

-30°C to +150°C [-20°F to +300°F]

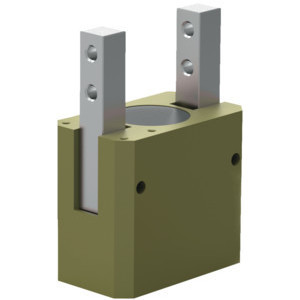

DPG-10M-2

Features:

- Rugged general purpose modular gripper

- Multi-position sensing up to 4 locations

- Shielded gripper to repel metal chips and particulates

- Spring assist option maintains grip in case of air pressure loss

- Synchronous or non-synchronous jaw operation

- Multiple air ports support manifold interface using O-rings

- Two finger mounting surfaces on each jaw

Applications:

- CNC Machining applications

- Chip and dry particulate harsh environments

- Non-synchronous jaw or fixed jaw clamp operations

RPW-625M-1 RPW-625M-2

Robohand Parallel Gripper

Features:

- Wide Parts, Long fingers, Heavy Duty

- Grip force ranges from 222N(50lbs) thru 2091N(470lbs)

- Strokes range from 19mm thru 114mm

- Rack and pinion design for smooth operation

- Jaws well supported to grip large and wide parts

- Double rod seals for extended life in harsh environments

- Optional non-synchronous jaw operation

2-Jaw Heavy-Duty Parallel Grippers Direct-connect Parallel Wide DPW-250M-1 DPW-250M-2 DPW-375M-1 DPW375M-2 DPW-500M-1 DPW500M2

Features:

- Robust wide body gripper with DIRECTCONNECT mounting

- Grip force ranges from 222N thru 800N (180 lbs)

- Strokes range from 19mm thru 63.5mm

- Rack and pinion design for smooth operation

- Jaws well supported to grip large and wide parts

- Multiple air ports where top ports can be manifolded

- Shaft wiper seals for harsh environments

- Optional non-synchronous jaw operation

RA Robohand Angular – Cam

Features:

- Highly reliable rugged general purpose gripper

- High grip force to size ratio due to cam driven design

- Fingers can be mounted on the side or top of jaws.

- Optional Viton® seals for high temp -30°C to +150°C [-20°F to +300°F]

- Use up to 2 magneto resistive sensors

Applications:

- Industrial assembly machines

- OEM pick and place machines

- General purpose gripping

RA-L Robohand Angular-Lock

Features:

- Highly reliable rugged general purpose gripper

- Very high grip force to size ratio due to toggle mechanism

- True Failsafe with toggle locking jaws, cannot release part without air

- Optional Viton® seals for high temperatures

-30°C to +150°C [-20°F to +300°F] - Optional inductive sensors and flow controls

Applications:

- Requiring internal/external toggle grip locking

- Internal gripping Applications without locking

- Industrial assembly machines

- OEM pick and place machines

RR Robohand Rotary – Light-Duty

Rotary Actuators Series 18, 28, 36 Angle 0-180 deg Payload .45 – 3.6 Kg

Features:

- Ultra-thin profile for tight space applications

- Preloaded bearings for high repeatability rotary actuation

- Zero backlash and slip fit dowel pins for precision applications

- Built-in adjustable hard-stops

- Optional manifold eliminates twisted airlines

- CR- Clean room option or for use in harsh environment applications

Applications:

- Precision rotary positioning

- Medical applications

- OEM machines

G110 Series OEM parallel

Features:

- 20 different models sized to, your application needs

- Fast actuations from 60mS

- Multiple stroke options, from 5mm to 50mm

- High grip force, small package, from 56N to 558N [13 to 125 lbf]

- Shielded design for clean to moderate, manufacturing environments

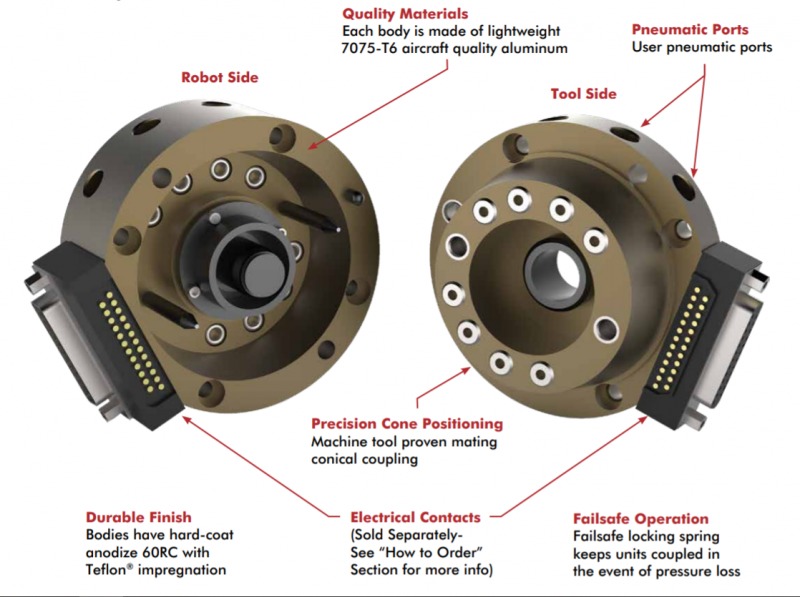

Automatic Tool Changers – RHC Series

Destaco’s RHC Series of EOA modular robot tool changers lead the industry with self-lubricating seals, pneumatic ports, precision cone positioning, and failsafe operation. A wide variety of utilities are available to quick disconnect, I/O, air, water, weld power, servo power, vacuum lines. These models feature a simple locking mechanism, high weight to payload ratio in the industry, and hard anodize for improved wear over long periods.

Manual Tool Changers – TC1 Series

DESTACO’s TC1 Series tool changers are ultralight, compact, and ideal for cobot work cells and applications requiring custom coupling solutions. Designed for safety, ease of use, durability, and excellent repeatability, this tool changer features a very low profile and a coupling solution with pneumatic and electrical pass-thru capability. The tool changer features IS0 9409 mounting, plus a highly adaptive blank version that is easily modified by machine builders for application specific needs.

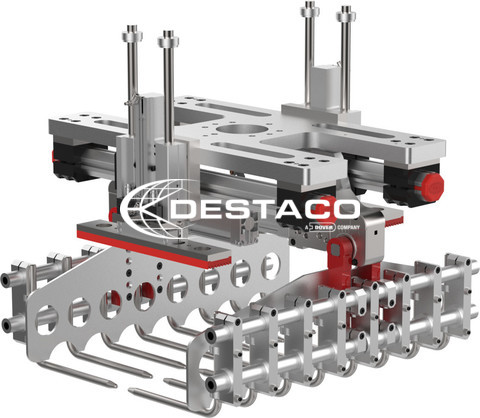

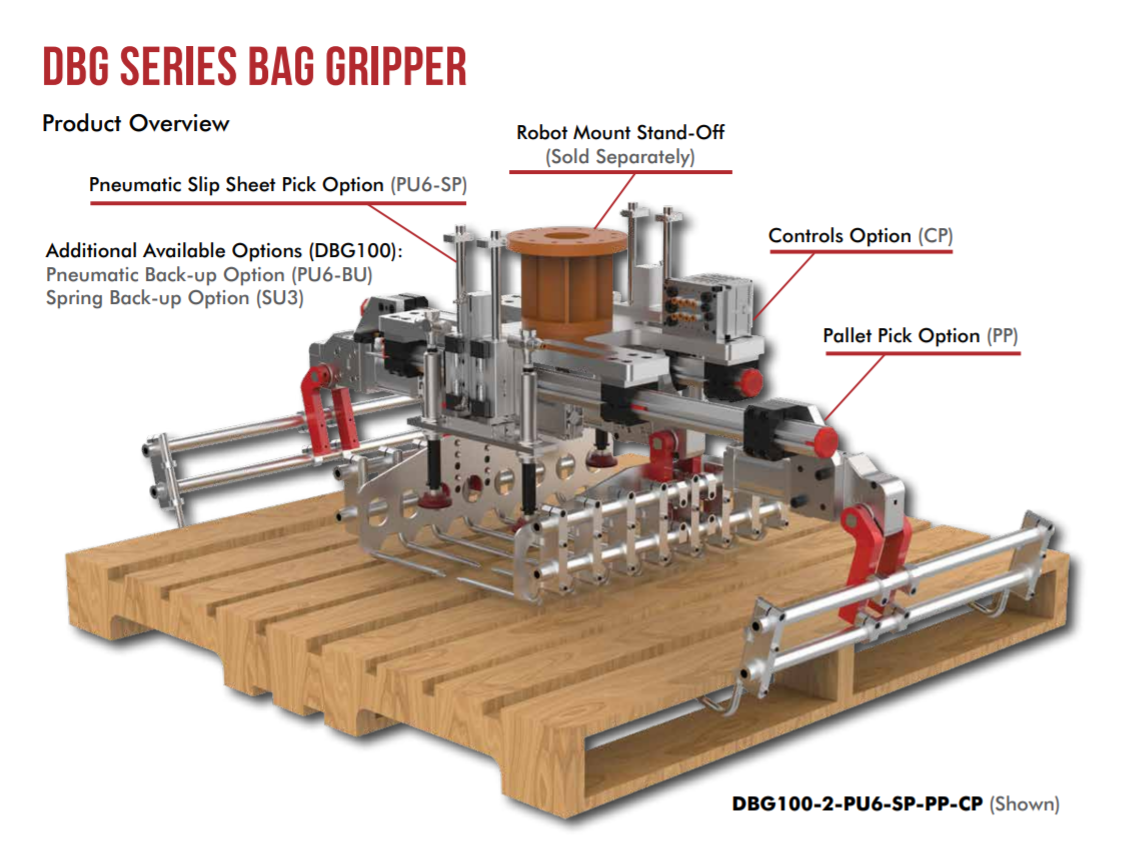

Bag Gripping and Palletizing

DBG50 (50lb Max Load)

DBG100 (100lb Max Load)

DESTACO DBG Series bag gripping end

effector solutions offers end of line pick and

place and palletizing solutions. The DBG

has a simplified design with field adjustable

finger position and opening angle.

Features also include:

Pneumatic or electric fully enclosed actuators

Integrated open/closed position sensors

Standard off-the-shelf components

VACUUM CUP GRIPPING

TC1 TOOL Changer

QC / TP Tool Changer

Tool Changer

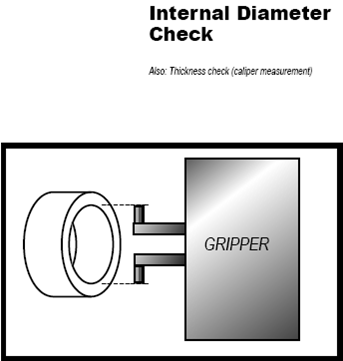

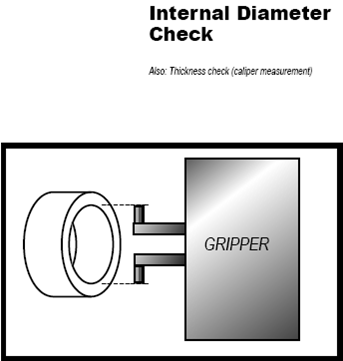

SMAC GRP Series resolutions: GRP20: 1µm standard and 0.1µm optional. GRP35 and GRP50: 5µm standard, 1µm, 0.5µm and 0.1µm optional.

Standard: 24 Volts single coil OPTION:I: 48 volt coil OPTION: Double coil some 24 volt coil Extra long life linear guide low friction linear guide

SMAC GRP Series

The GRP Series gripper offers a peak force up to 45N, and a working stroke up to 30mm. The built-in linear encoder delivers 0.1 micron precision.

Features

- Precision positioning ideal for measurements

- Soft-Land capability for sensing product location and dimensions

- Data feedback

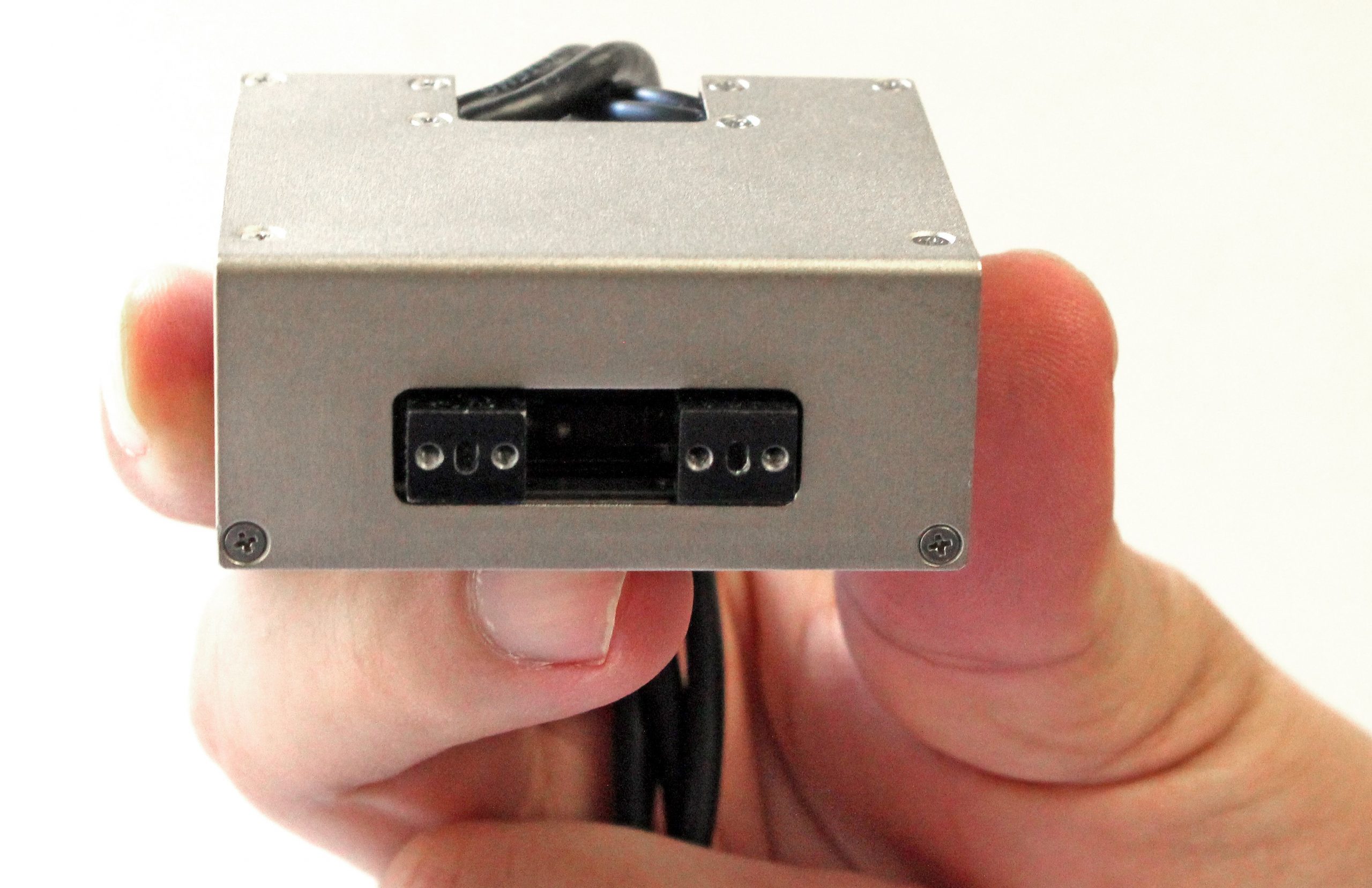

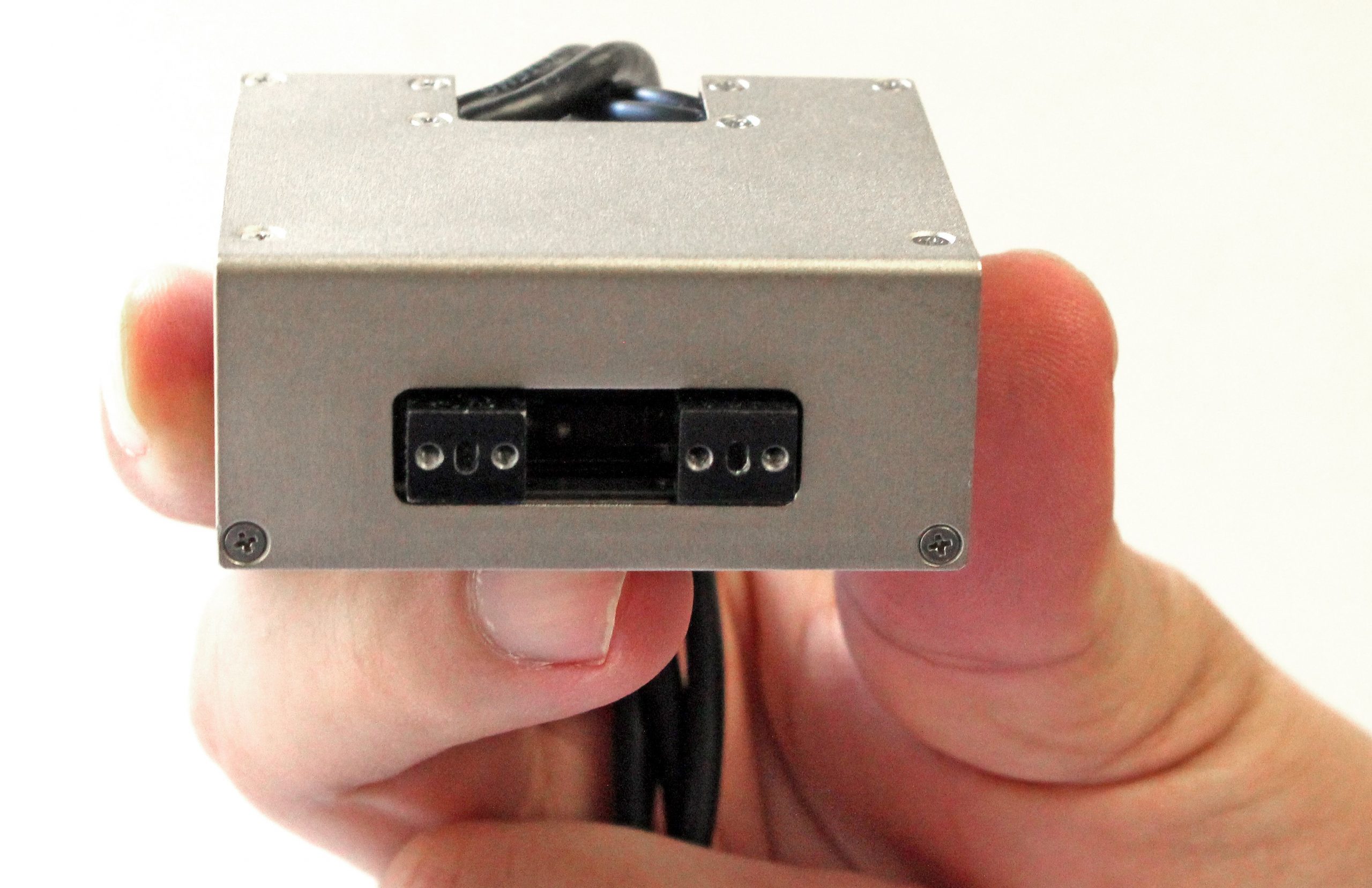

SMAC

Force Sensing Gripper

Features

- Compact and lightweight

- Light force capability 10g or less

- Soft-Land capability for pick and place of delicate and fragile parts

- Each jaw can be independently controlled in force, position and velocity

- 1 micron linear encoder standard

- SMAC’s Patented ‘Soft-Land’ technology

Fully programmable in force, position and velocity

MGR Series

Specifications:

Dimensions [mm] 55×47.5×24

Stroke [mm] 10 (5 each)

Peak Force [N] 3.8 @ 24VDC

Encoder Resolution [µm] 1

SMAC’s Patented ‘Soft-Land’ technology

Fully programmable in force, position and velocity.

Controllers:

LAC-1 x2

LCC-10(11) x2

LAC-26